HHP Manor work on large scale growing with the corresponding large scale irrigation. Their water supplies are reservoirs which typically create very little water pressure to supply the pumping system operating as they do on a volume based pumping system.

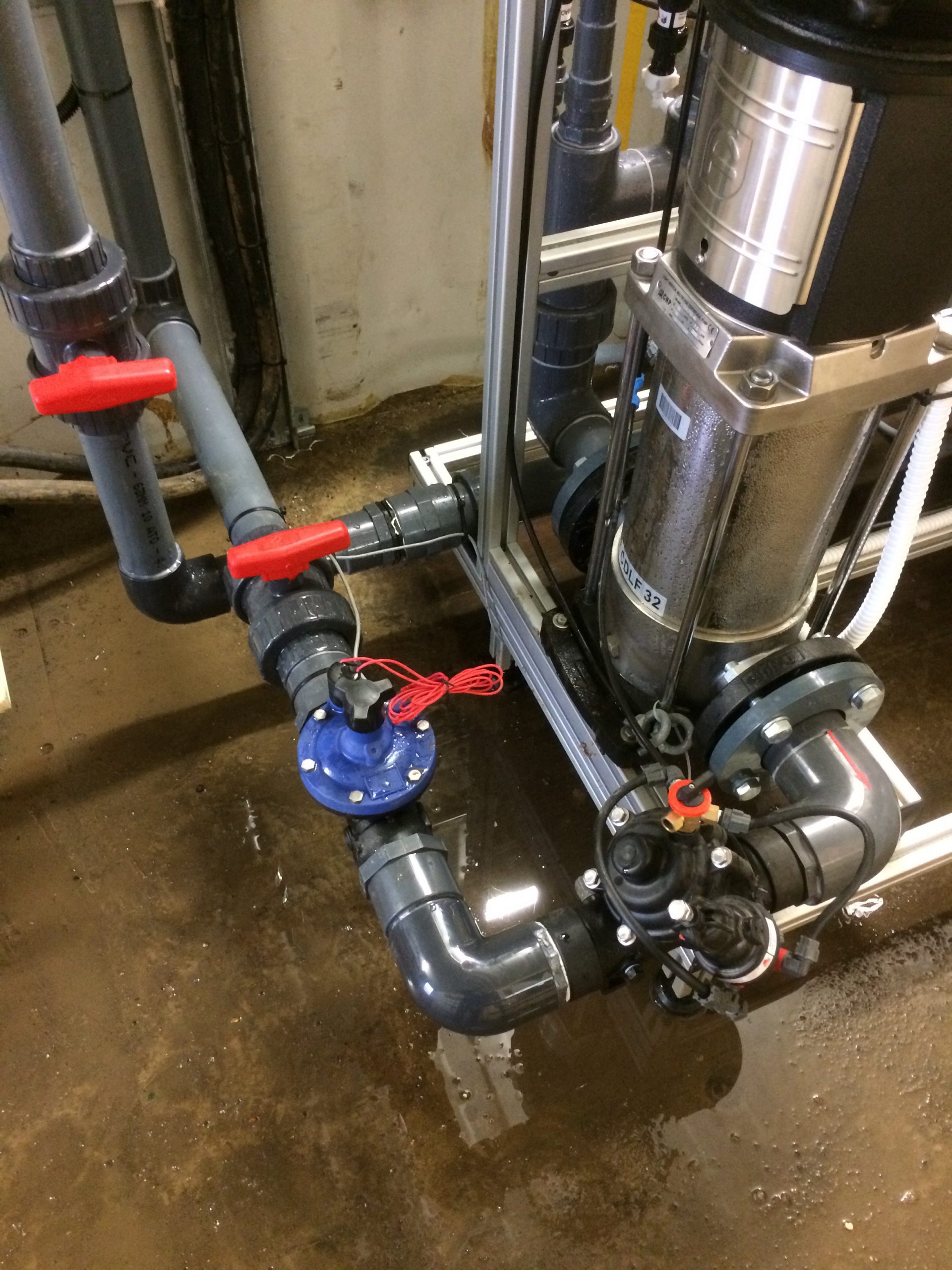

Ripple Aquaplast designed a system using a speed controlled 110m³/hr submersible pump to push the water to the crop via a 6″ NaanDanJain automatic back flush 130 micron filter. To power this pump a generator is automatically started by the NDJ Spirit Pro controller. Ripple Aquaplast used an in line fertiliser rig complete with 8 Bar booster pump to allow the addition of fertilisers and acid but without decreasing the system flow rate.

HHP Manor are the first company to utilise a seven fertiliser and one acid venturi injection system with 1000 litre/hour flow rates.

HHP took their irrigation information one step further. They realised that the historical data being created could have an impact on their future irrigation, as such, they invested into a Windows based PC network. The Greenline software interprets and stores all the information in a user friendly format that can be interrogated from any PC, laptop or smartphone with the correct password.

Finally to the field; the terrain created a few problems initially with run down on the drippers even though the NDJ dripper has a 3 closing pressure. The RA team brought their integrated laser measurement system to create a 3d effect of where the field slopes are. With the quick installation of the market leading LPD’s the problem was removed.