DGT by Senmatic develops sustainable technology solutions for modern horticultural production, ranging from greenhouses and garden centers to large-scale vertical farms and research facilities.

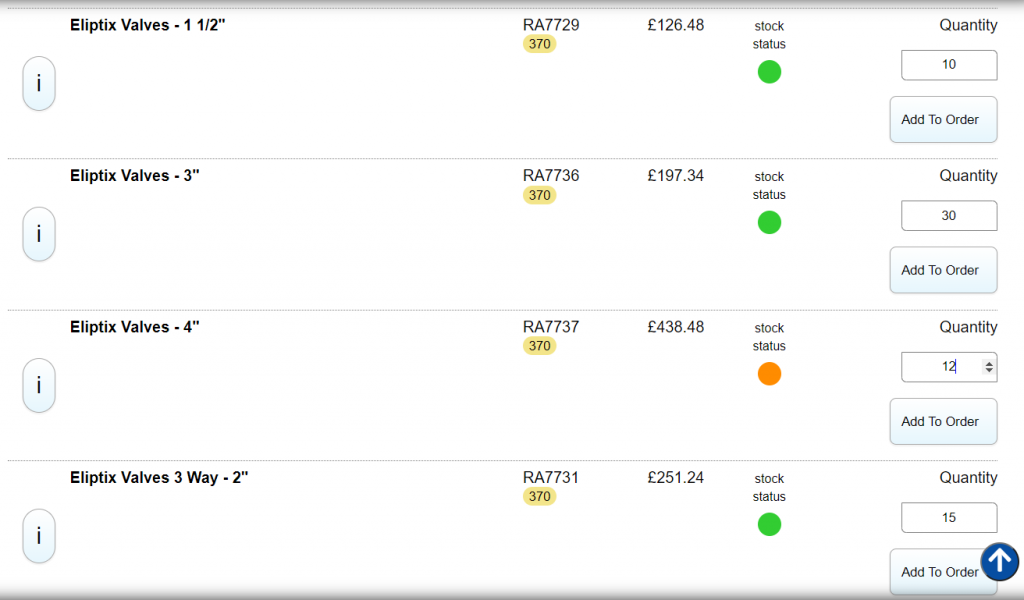

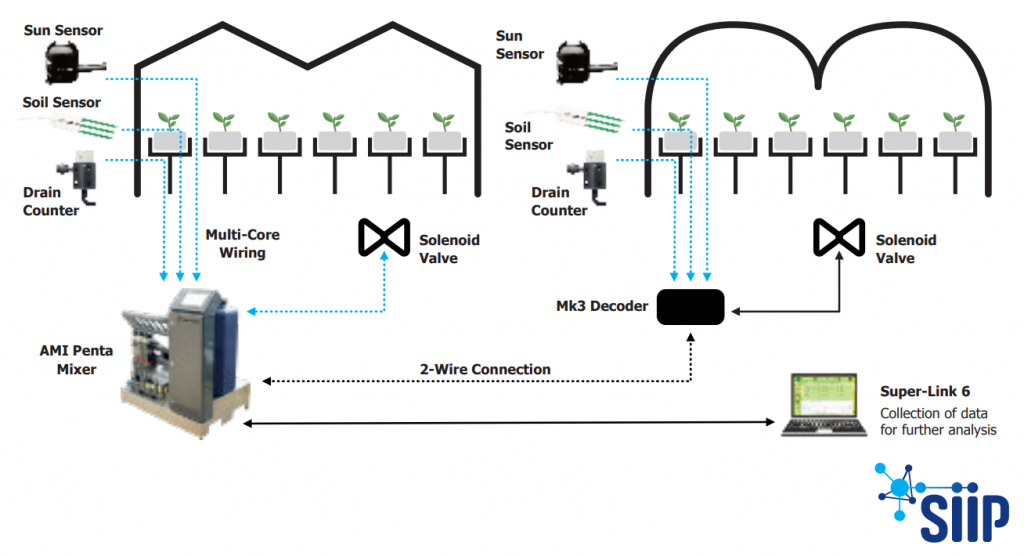

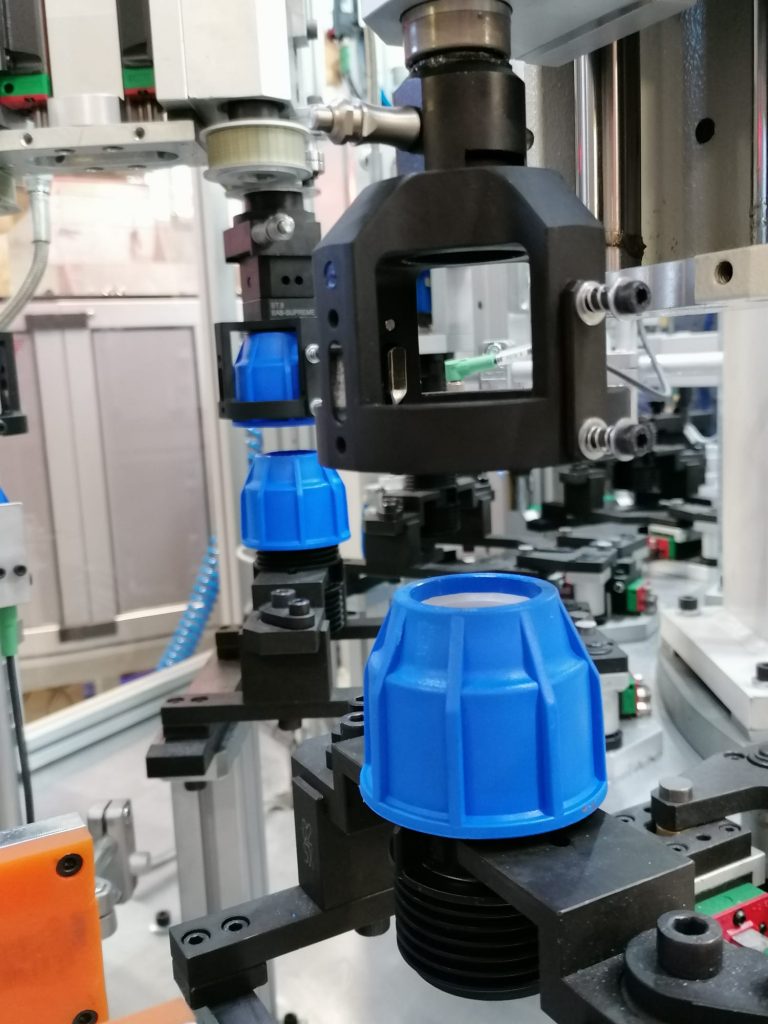

They specialize in controller technology for optimization of crop growth and product efficiency, and deliver complete and configurable solutions for horticultural applications, such as electronic and mechanical climate control, irrigation and fertilizer mixing, and horticulture LED grow lights. We also offer full line solutions built from our wide and deep product range.

Our product range provides 360° management of your installation – from complete climate control solutions and flexible fertilizer mixing systems to management software and powerful LED fixtures delivered as single product solutions or full line solutions. We have an outside-in perspective: we develop products with customers for customers.

Reliability, user-friendliness and the possibility of combining and configuring our systems and products keep us at the forefront of the horticultural industry. Our controls are all tested on-site at commercial greenhouses during development.

Put simply, we develop state-of-the-art products with long life spans that improve your return on investment.

Your sustainable technology partner

Our products allow you to create healthier crops under full control – even where climate traditionally would be a challenge for production. We focus on developing products that enable sustainable production for all our customers.

In addition to products offering improved sustainability, we work with three of the 17 Sustainable Development Goals. Read more on how we work with sustainability here.

Their history

Founded under the name DGT (Danish Greenhouse Technology) in 1956, we bring more than 65 years’ experience to the table. In 2004, DGT was acquired by Micro Matic and placed under Senmatic and in that connection renamed to Senmatic. As of today, the two names have been combined and we are now known as DGT by Senmatic.

Who will you meet at DGT by Senmatic?

We highly value personal corporation with all customers, small or large. Working closely with our customers is the key to our success, and why we are one of the leading global suppliers of horticultural controls and equipment. It is also why our sales team consists of horticultural growers and technicians: they truly know their way around a greenhouse and with their extensive hands-on experience they can guide you to solutions that match your exact needs.

With distributors in more than 20 countries, we support customers on most continents. Most of our distributors have cooperated with us for many years. They are all very technical skilled and highly qualified in supporting you in our product range and how to ensure you the best solution.