Soft Fruit Grower in Perthshire

Andrew Barrie owns and runs a significant soft fruit – both raspberries and strawberries – operation near the picturesque Vale of Strathmore in Perthshire, near the towns of Couper Angus and Blairgowrie. Colbeggie Farm takes pride in offering only the highest quality fruits which all goes to the supermarkets.

Andrew also takes great pride in his team and wanted to invest in upgrading the water supply to the staff accommodation for use in their showers, kitchens and general areas.

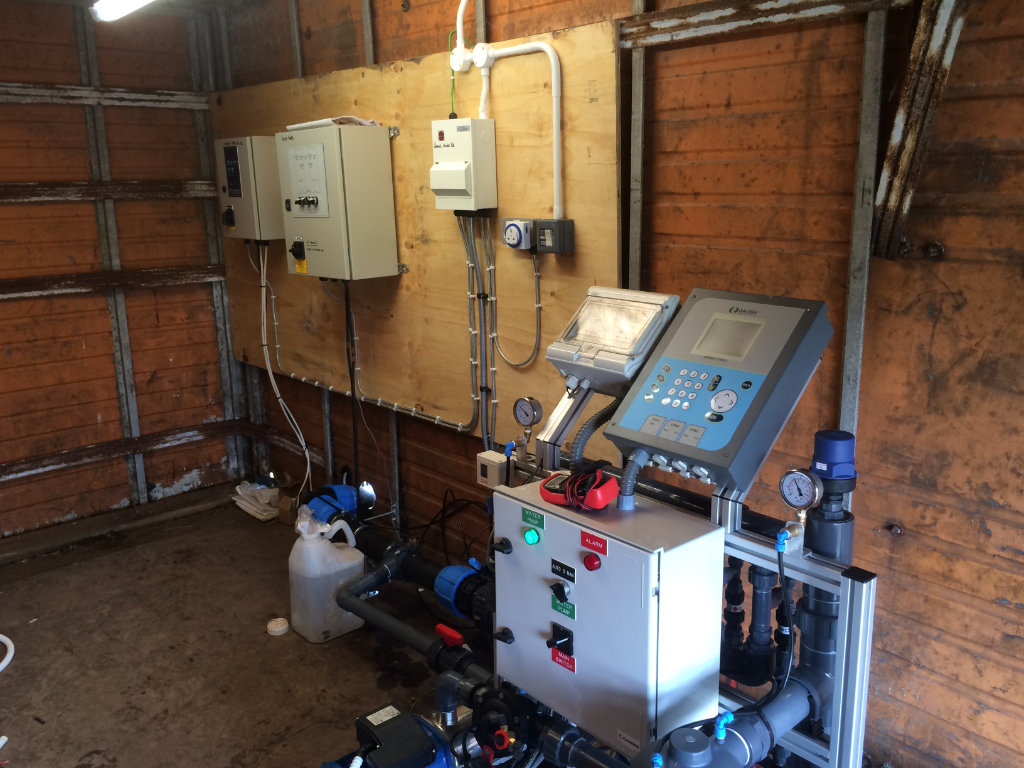

Following a site visit, Ripple Aquaplast’s technical team designed, supplied, installed and commissioned a new potable water supply by linking a borehole. 50,000 litre covered water storage tanks to WRAS approval, a twin variable speed pump set to supply 6m³/h of drinking water to the suite. Further expansion is planned in the coming months.